Reliability testing is of massive importance to the eventual success of any technology. Depending on the chosen testing strategy, devising, setting up and implementing reliability testing systems can introduce monumental challenges for a variety of reasons.

Attempting to build an in-house testing system can seem like an attractive approach at first glance, with potential initial cost savings and total control over the process. However, this option overlooks crucial long-term considerations including:

- Do other frequency ranges need to be tested down the line?

- Are current levels of expertise and bandwidth enough to both support and scale the testing equipment?

- Is the physical space available to dedicate to this equipment long-term?

- Can reliability be credibly demonstrated to customers through an in-house testing approach?

Luckily for the businesses and consumers who will benefit from the next wave of innovation, another alternative exists. With Accel-RF’s years of experience and development expertise, in-house reliability engineers can leverage a modular, flexible approach that gets an operation up and running quickly. In-depth training and support also ensure that engineers can execute complex testing schemes without a surplus of internal resources and support staff. Accel-RF becomes a partner to ensure years of successful testing and can advise upon changing testing needs along the way.

Partnering for Your Success

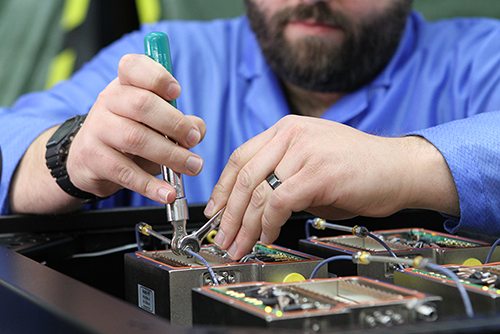

The challenges of reliability testing are multifaceted and require a team of high-level resources to address. A typical team includes a lead reliability engineer or semiconductor physicist supported by a group of test engineers and technicians. The technicians implement the test plans developed by the lead engineer while also working on the upkeep and calibration of the equipment. The reliability engineer must analyze large quantities of data collected during the test. All of these different functions rely on software control, so a user interface that seamlessly handles all aspects of the testing is invaluable. Accel-RF brings decades of expertise on these pertinent topics to train key people to use the different aspects of the system.

Expertise Requirements

Accel-RF works with operations of all shapes and sizes, and usually, partners with the semiconductor physicist or reliability engineer at a manufacturer tasked with performing tests to characterize and improve the reliability and yield of their devices. The partner company likely has some level of RF and microwave design expertise, although it is typically in a separate organization from the reliability group and might not even be in the same location. Reliability testing of RF devices requires a high level of knowledge of high-frequency circuit design due to the challenges of testing at elevated temperatures. Designing a suitable RF interface to the device-under-test to cover a wide range of frequencies and temperatures is not usually in the typical core competencies of the reliability test group. Support from the in-house RF design group might also not be possible due to their own bandwidth limitations. In this situation, the reliability group can draw on Accel-RF’s wealth of expertise in RF circuit design.

The promise of Artificial Intelligence (AI), the Internet of Things (IoT), Virtual Reality (VR), Augmented Reality (AR), Autonomous Vehicles (AV) and a host of other new ways to mesh human and digital existence all depend on one linchpin: 5G technology.

Beyond the technical expertise needed to execute the testing, sales and marketing teams will also want knowledge of the results, such as expected lifetime or yield data, as this info can become a powerful piece of their arsenal when it comes to showcasing the product’s reliability.

All of the above internal staff members play a key role in ensuring the company leverages the system to its full capabilities. Accel-RF will work with each party during training and on-boarding to confirm they are comfortable in their role in the reliability testing journey.

Accel-RF vs In-House Solution

For a company considering developing its own in-house system, they will most likely need to purchase an assortment of off-the-shelf components, power supplies, ovens, and other tools. Then they’ll need to combine all of the parts, determine how to fixture the devices, and write a custom program to control it all. The real difficulty, however, lies in getting to the point where they're confident the data being produced is of value, which could require thousands of dollars and hundreds of hours of trial and error.

When a company opts to develop their own in-house system, they're essentially undertaking two projects. The first is to develop and prove out the test system, followed by the second step of actually performing the tests. In the end, this delays the time to the end goal, which is testing their devices and getting the data they need. The Accel-RF systems allow users to access valuable data quickly by bypassing the entire development process, allowing them to get their devices tested and get their product to market, opening up opportunities for first-mover advantages.

Let’s look at two important reasons why an Accel-RF solution is the best long-term reliability investment: flexibility of the equipment, and lab space requirements.

Flexible and Modular

For devices running at Ka-Band frequencies, constructing an in-house test system capable of precise RF measurement over a wide dynamic range and at elevated temperatures is a significant undertaking. Even if the engineers can construct the equipment necessary for testing this current product, they still have to consider the possibility that the operating frequencies they are testing now will shift significantly over the next two, five, or ten years. A huge differentiation between an Accel-RF system and an in-house model is the capability to migrate the system to different frequencies, packages, and/or types of devices. While it may seem simpler or more economical to opt for an in-house solution built for a specific device, frequency, or project, it’s important for test engineers and leadership to think about both their short-term and long-term testing needs. As tempting as it may be to opt for an in-house solution for an isolated test-case, as devices become more and more mature, leadership may want to broaden their market base so they can sell into more areas. A less flexible in-house method makes it hard to get that system modified to meet new testing requirements at this inflection point, forcing them to continually tear down and rebuild for new requirements.

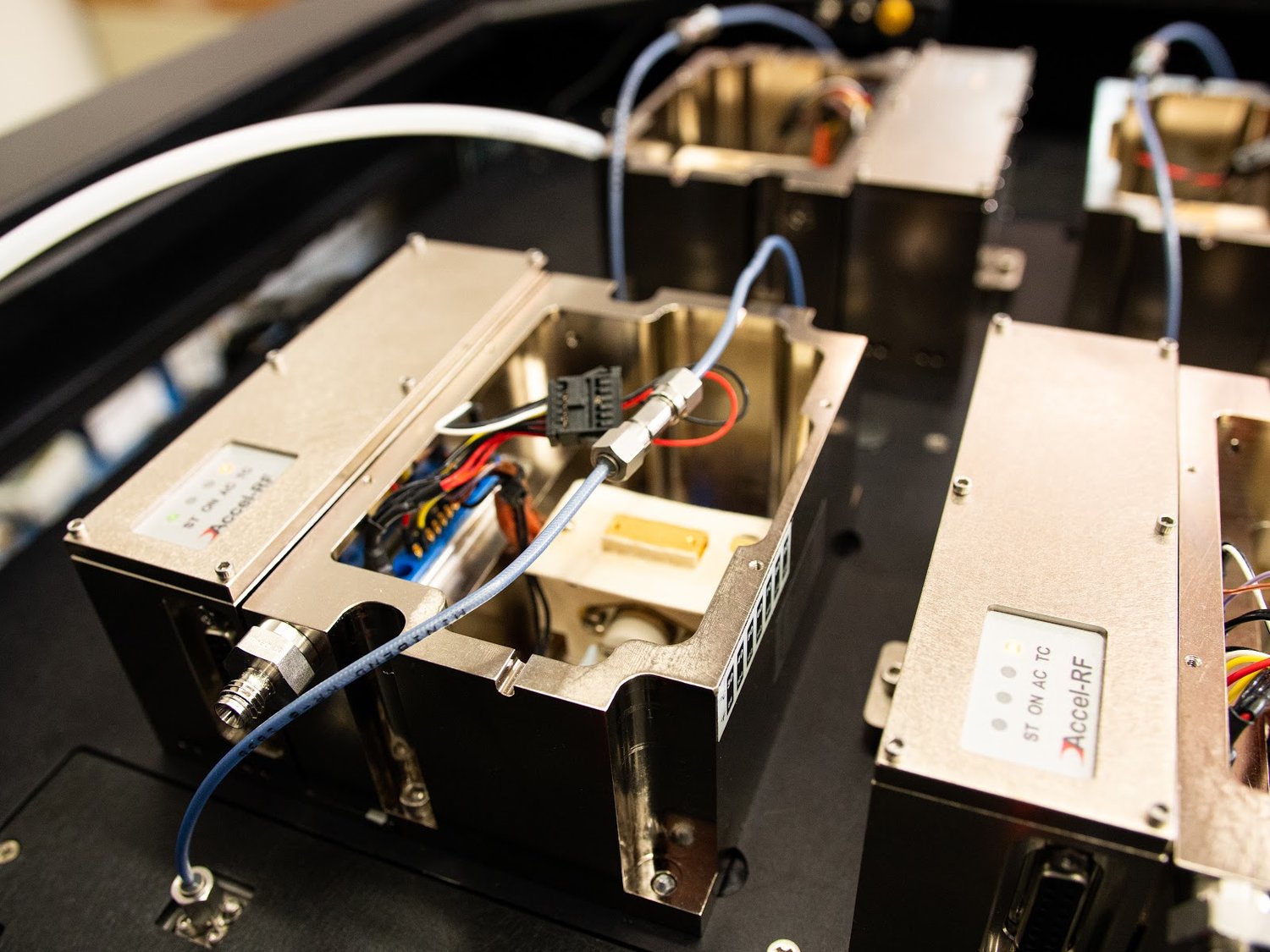

Conversely, with an Accel-RF system, the challenges of implementing a high frequency, high-temperature, multi-channel RF life test system have already been solved thanks to years of experience serving the industry. This allows for quick implementation and adjustment periods to new testing ranges. Because the system is completely full-featured and turnkey, the only step to get it up and running is plugging it in and turning it on.

Space Savings

Another major advantage of Accel-RF equipment compared to an in-house implementation is the size of the system and the space it occupies. The equipment is a turnkey, integrated system that has a significantly reduced lab footprint compared to the size of internal implementation. Because of the integrated power supply, RF, and thermal characteristics, Accel-RF makes the technology very modular in its concept, greatly reducing the size of the equipment. It’s of tremendous importance to consider the opportunity cost of utilizing precious lab space for bulky, unintegrated in-house testing equipment.

Training and Implementation of Accel-RF systems

Accel-RF’s full training and on-boarding processes ensure an engineering team can execute their testing without delays in their go-to-market timeline. Qualified Accel-RF engineers visit to conduct on-site classroom-style training that goes over the theory of reliability testing, and how the system and software operate. The robust Accel-RF LifeTest software is the main learning curve of the training phase. Because the equipment is modular and flexible, it is important for the Accel-RF team to understand exactly what a customer’s testing goals are in order to customize the system to their unique needs. With that in mind, during the on-boarding process, Accel-RF also includes the development of an action plan based around the customer’s goals — helping them come up with a test plan, set up devices and configure the test in the LifeTest software.

The training is thorough and spans roughly three days, spending two half-days in a classroom environment. The rest of the time is spent running the system in real-time. This includes all the necessary test setup, monitoring, analysis, and calibration knowledge the customer will need to be completely self-sufficient.

Ideally, the third day of training is spent testing actual customer devices in the way they plan to utilize the system. This starts with the mounting of a device into a test fixture and performance validation in the system using the LifeTest software controls. From there, the eventual goal is to configure a sophisticated AutoSequence routine as the means to perform the actual test. Using AutoSequence, the user can script an automated test routine involving numerous steps and durations. This can involve recurring down-point measurements using a characterization test in order to track changes in the device at a lower temperature before ramping back up to the elevated stress temperature. Once an operator understands how to build and fine-tune an AutoSequence, they will be able to develop an array of test plans entirely on their own.

By the time the training is complete, there are typically devices up on the test and collecting valuable data. Even after their departure, Accel-RF engineers are available to help analyze that data going forward and to assist in configuring new tests as requirements change.

Symbiotic Relationship

Beyond having a robust, flexible test system that produces results you can trust, one of the main benefits to Accel-RF customers is the change in perspective it can provide. Because an integrated RF/DC temperature test is difficult to execute, customers may not have experience with this form of testing that unlocks previously unknown insights about their technology. Once people become privy to these insights, they begin to use their new perspective to formulate new ideas and strategies. Commonly, after the first six months to a year working with the system, customers will develop data-driven, creative ideas and techniques to improve the performance of their overall technology.

When Accel-RF innovates, it allows its users to leverage the latest and greatest technology to develop groundbreaking advances in their own processes. This symbiotic relationship not only empowers the product team, but it can also inspire the marketing and sales teams, as they can provide customers with new insights and a different way of looking at their market.