Table of Contents

- Increased Use of New Semiconductor Materials Magnifies

Importance of Efficient Reliability Testing Solutions - The Evolving Needs of Reliability Testing

- Reliability Leads to Predictable Performance with Age

- The Downside to In-House Reliability Testing

- Modular Testing Streamlines Testing

- Accel-RF Plug-and-Play Modules Expand Possibilities

- Cost Benefits Favor Accel-RF Solutions

- Trust Strengthened Through Application of Consistent Standards

- The Distinct Advantage of Accel-RF Modular Flexibility

Increased Use of New Semiconductor Materials Magnifies Importance of Efficient Reliability Testing Solutions

Device designers, product manufacturers, system integrators, and government supply chain vendors across a wide swath of the electronics industry all share a common challenge. None of them can afford to let reliability testing slow them down. To win the contract, get the order, make the deal, companies must show proof that their solution will function as promised over an intended lifetime, and they have to do it quickly.

New high-performance semiconductor materials are finding their way into devices used in a variety of applications. Whether it is renewable energy, with its need for fast and reliable power switching or the stringency of space applications where enduring high-performance in harsh environments is needed, sophisticated new technologies are increasing at astounding rates. Developers often find themselves in a race to test devices under different power levels and frequencies as designers come up with new ways to take advantage of these technologies’ superior abilities.

The stakes are too high, and the development cycle is moving too rapidly to risk setbacks because a device in the field failed to function as expected. Enter the concept of modular testing solutions pioneered by Accel-RF. Through working closely with device manufacturers in a variety of industries for nearly two decades, Accel-RF determined a unifying thread connecting everyone in the arena: they all need extreme flexibility in reliability testing solutions.

Want more information on extreme flexibility in reliability testing solutions?

The Evolving Needs of Reliability Testing

The use of a new generation of compound semiconductors like GaN across various applications is placing a new emphasis on the importance of reliability testing. GaN devices, unlike those based on silicon, do not have a long history of characterization data to extrapolate into predictions about how well the device will perform in different applications. Developers must provide reliability data for existing devices designed initially to work at different power levels and frequencies plus test new ones. Increasingly narrower development cycles create the challenge of how to efficiently perform a wide variety of qualifying tests on a large number of different devices.

As designers develop GaN devices for one application, product developers often realize multiple uses for the same device. For example, a high-speed power switch needed for smoothly integrating wind-generated electricity into the power grid could also serve in a circuit that helps an electric vehicle get more mileage per charge. One primary requirement for the manufacturer would be to provide characterization data for the same device operated at the two different power levels and frequencies needed for each application. Setting up different testbeds to conduct each set of reliability tests is feasible, but not very efficient. If the manufacturer wants to add another utilization, say in a power inverter for a solar panel, another entire section of testing infrastructure is needed.

Reliability Leads to Predictable Performance with Age

Depending on the final application, many of the parameters described below will be critical factors in determining that a device meets its performance goals. Each device will have a product lifetime or mission life and these goals must be hit when the product first goes live and throughout operation until it reaches that lifetime.

Accel-RF’s systems are designed to track how certain parameters will change with age and operation to ensure a product’s success in the field.

Our Industries

(Touch to learn more)

1

DC Bias Current

2

RF Output Power

3

RF Gain

4

Ohmic Contact Resistance

5

Intermodulation Distortion

6

Phase Noise

7

Noise Figure

8

Signal Linearity

9

Switching Response Time

10

Frequency Stability

Ohmic Contact Resistance

In semiconductors, this is the intrinsic resistance through the metalized terminals of the device into the channel or junction. A physical change in the ohmic contacts, which can be an effect of metal migration, can change the resistance and impact the electrical performance of a device.

Industries:

![]()

![]()

Intermodulation Distortion

IMD occurs when two signals are present in a nonlinear system, such as an amplifier. The frequency harmonics of these two signals mix and create 2nd and 3rd order intermodulation products. Measuring and mitigating these distortion levels are critical for communication applications.

Industries:

![]()

![]()

![]()

![]()

Phase Noise

Commonly referred to as “jitter”, phase noise is the random fluctuations of the phase of a signal source. It is present in oscillators and digital clocks and can have detrimental effects on a system where frequency conversion takes place. A signal with high phase noise can end up occupying more of the spectrum than intended and introduce error.

Industries:

![]()

![]()

![]()

![]()

Noise Figure

This is a critical parameter in all Receiver designs. The Noise Figure must be low for a system to be sensitive enough to detect and process weak signals. Low Noise Amplifiers (LNA) are typically the first element in a receiver and are designed to minimize Noise Figure.

Industries:

![]()

![]()

![]()

![]()

![]()

Signal Linearity

For amplifiers in RF applications, this represents the relationship between the input power and the output power of a device. At low input power levels, linearity is uniformly quantified by the gain. As input drive increases, the device gain compresses as the device saturates and the linearity characteristics change.

Industries:

![]()

![]()

![]()

![]()

![]()

Frequency Stability

This represents the ability of a source, such as an oscillator, to maintain a constant frequency output. Outside influences such as temperature and change in bias voltage can lead to drift and affect frequency stability. Stability in communication systems is required so that a signal does not drift outside of its designated band.

Industries:

![]()

![]()

![]()

![]()

![]()

![]()

The Downside to In-House Reliability Test equipment

Many companies opt to build their reliability test equipment in-house. With a talent pool consisting of hardware and software engineers qualified to devise adequate testing solutions, it can seem like the most fitting solution. When faced with a tight deadline to verify reliability, putting together in-house equipment eliminates the need for contracting with outside entities, getting them up to speed on the project and then trusting the results they produce.

The problem with the in-house solution is that it usually results in proprietary testing rigs designed for one particular device under one specific set of conditions. When the testing parameters change or a new device needs testing, the in-house team must create a new testbed. The old equipment often ends up in the corner unused, collecting dust.

Modular Testing Streamlines Testing

Accel-RF started out manufacturing RF and DC life test equipment, so they understand the challenges of the extreme bandwidth ranges in use today. The new emerging compound semiconductor technologies, such as gallium nitride (GaN), silicon carbide (SiC) and others do not have the same wealth of reported reliability data as silicon or even gallium arsenide (GaAs). So, the testing burden placed on manufacturers continues to expand at an ever-higher rate.

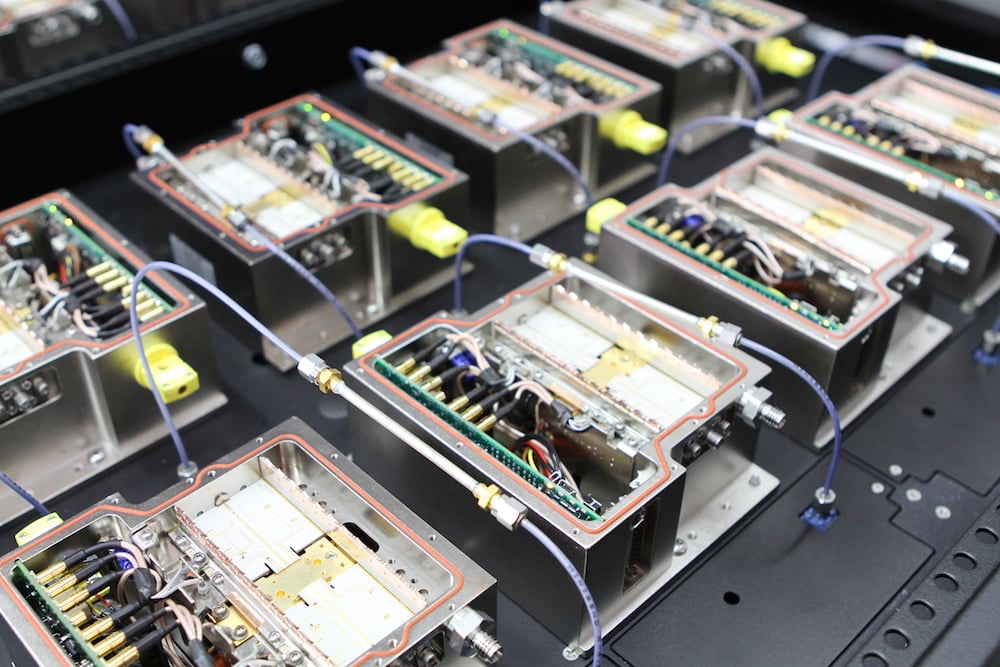

Accel-RF approaches the problem starting with adaptable fixture designs that offer developers options for setting up configurations to meet a variety of testing needs. Instead of having to start from scratch each time a new project injects different testing requirements, the test engineers can reconfigure the existing equipment to run under the new parameters.

The test fixtures mount into a fully integrated test system that was also conceptualized with modularity in mind. The baseline DC, RF, and thermal control elements all cover wide operating ranges from the start, but their plug-and-play implementation in the system enables easy reconfiguration when needed. When a different power supply or driver amplifier is needed, the end-user can easily handle that installation without having to worry about support from Accel-RF for a site visit or factory rework. This approach keeps the system fully utilized with minimal down-time.

The result of this strategy is a higher capacity for performing tests when requirements change at a vastly increased speed. Considering the pace at which developers are advancing GaN technology and product manufacturers are incorporating the new devices in a multitude of applications, going modular with reliability testing is the only way to keep up and stay competitive.

Accel-RF Plug-and-Play Modules Expand Possibilities

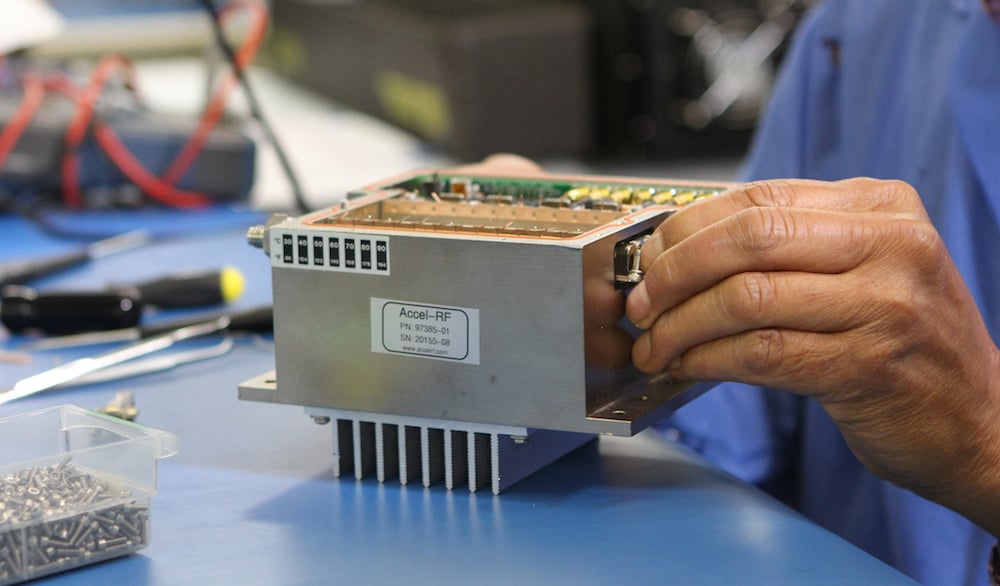

Focusing on the needs of customers led Accel-RF to evolve the concept of testing modularly into a line of plug-and-play SMART Modules. These testing building blocks allow users to swap out components of the core system to change testing parameters and upgrade features.

Accel-RF continues to add new fixtures to the line of plug-and-play SMART Modules. The main idea is to upgrade customers' existing test equipment, whether they purchased it from Accel-RF or home-brewed it themselves, to allow them to follow the continuum of new technologies as they come on the scene.

Here are some notable members of the SMART Module set that can help give manufacturers a developmental edge in the current market.

- Characterization Platform: Independent single-channel or virtual multi-channel characterization test subsystem. Provides temperature, RF-signal and bias-control to measure semiconductor performance.

- Quantum SMART Fixture: The Quantum SMART Fixture is designed to accept and test existing customer modules or evaluation circuits with built-in temperature and pulsed bias control.

- Multi-Channel Benchtop DC-HTOL: Flexible, integrated software and hardware platform capable of functioning as an independent 12-channel or virtual multi-channel characterization test subsystem. System tests multiple devices at a wide array of DC bias settings at elevated temperatures. Ideal for long-duration semiconductor high-temperature operating life (HTOL) or accelerated life tests (ALT).

- RF-Ready DC Fixture: Operates at elevated temperatures for thousands of hours with consistent RF/DC outputs. Designed for proper impedance matching for RF characterization.

Part of what makes these plug-and-play modules so attractive to users is the fact that they can add them to existing testing systems to enhance their capabilities. The modules work together to bridge gaps between existing equipment and needed new capacities. If a manufacturer started going down the road of in-house test development and then realized the need for a better solution, they do not necessarily have to start from scratch. Accel-RF’s modular solutions could be the missing pieces needed to construct an effective test setup.

Cost Benefits Favor Accel-RF Solutions

Ultimately, business decisions in any field are subject to a cost-benefit analysis. Overcoming the inertia associated with changing ingrained processes is difficult. Without the ability to point to definite advantages, reducible to dollars and cents, it is nearly impossible to improve existing processes.

Switching to a modular reliability testing method from an in-house system, which on the surface may seem to be working fine, is no exception. Often, those within the organization who understand the hidden costs and waste associated with a DIY testing approach must make a fiduciary case for the benefits of changing.

- Lab Space: Gone are the days of sprawling equipment rooms that could house abandoned test stands as in-house teams developed new ones to take their place. Lab space comes at an ever-greater premium, and developers face increasing pressure to maintain a compact testing lab footprint. Accel-RF modular designs use far less space than conventional setups, and since they are configurable, the space requirements can stay consistent as opposed to continually increasing.

- Time to Market: Dramatically cutting the lead time it takes to start providing customers accurate reliability data is a significant factor in deciding to embrace the modular testing system design. At every stage of the development cycle - design, device manufacturing, and product integration - the speed of development is often the determining factor for success. Access to accurate test data drives new technology advances and helps ensure an acceptable return for investors and stakeholders.

- Help For Marketing/Sales Teams: New technologies can be challenging to sell. Marketing and sales departments benefit from having access to hard data that shows the device in question will perform as promised. Reliability testing is a proven way to provide this data, but in-house testing is often too far behind the sales cycle to be useful. Early test data quickly put into the hands of marketing and sales gets the ball rolling and increases the chances of a successful launch.

The customizable modular approach enables Accel-RF to work closely with customers to define appropriate tests for almost any design in question. If done in-house, creating separate tests for every device and application becomes more costly and wasteful as time passes. Processing the collected data from so many different test scenarios into a useable format when done in-house creates an additional burden.

With Accel-RF modular test equipment, the flexibility inherent in the system allows for a complete focus on gleaning and cost-effectively presenting accurate data for any testing requirements that arise. As the future unfolds and different technology with innovative uses appear, companies can continue to reconfigure their existing testing rigs to meet the new challenges.

Trust Strengthened Through Application of Consistent Standards

As technology-driven products become part of the common infrastructure, government authorities become more involved in awarding contracts and setting performance standards. This oversight has always been the case with military and aerospace designs, and the trend is strengthening as new technology expands into areas like power transmission, renewable energy and wireless communications.

When a government agency awards multiple contracts to different manufacturers to provide separate batches of deliverables of the same product, the issue of testing consistency becomes paramount. Differences in testing methods or devices can cause unreliable data to creep into the project and jeopardize its success.

One solution for removing any doubt from the testing process is to require subcontractors to use the same testing equipment or methods. The modular design of Accel-RF equipment is well-suited to provide platforms for separate companies to test devices that need to maintain a high level of consistency.

Learn why Accel-RF equipment has become the preferred test partner for defense agencies and other federal contracts.

The Distinct Advantage of Accel-RF Modular Flexibility

Device manufacturers, product designers and system integrators increasingly realize the benefits of Accel-RF's modular approach to design testing. It allows them to quickly adapt their existing test systems to new markets with constantly fluctuating requirements by changing one or two components. Once testing facilities have the primary platform, they can economically configure testing for numerous power levels, frequencies and test channels.

They are still able to test in-house, but they have the flexibility of a modular system and the power of a seasoned software tool to process their testing data.

The company's cost of ownership goes down as its testing capacity increases since they only have to invest in modules and not wholly new systems.

Accel-RF modular testing allows customers to move from design to market as quickly as possible. It frees them from having to reinvent the wheel every time they need to test a new device or functionality. The bottom line is that Accel-RF delivers the ability to test devices quickly and accurately to obtain reliable characterization data, end-of-life statistical predictions and quality-enhancing burn-in testing.