Integrated circuit manufacturers are attempting to up their output to unprecedented levels to meet the demands of building the 5G infrastructure. As the pressure mounts to ready devices for a multitude of new products, companies are looking for ways to save both time and money. In this sprint to be first, where the margins are thin and the stakes are high, some might assert that using DC testing to define RF reliability performance is an effective strategy.

DC testing is less costly and plays a vital role in verifying the intrinsic reliability characteristics of newly designed ICs. It cannot, however, take the place of RF testing to determine the suitability of an RF device for a given application. Manufacturers that wish to stay competitive for the long-term in the emerging 5G market will need to adopt a strategy that leverages both RF and DC testing to achieve comprehensive results.

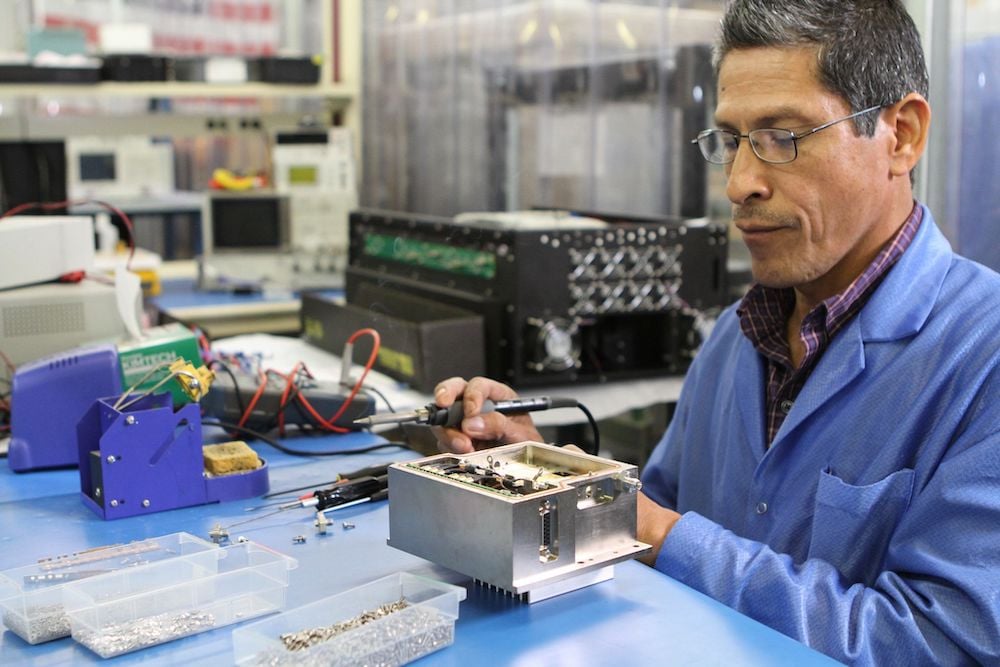

Accel-RF, a longstanding reliability testing solution provider, can help companies ensure that their devices will meet the demands of product developers. With fully scalable and modular designs, Accel-RF’s test systems offer the flexibility to perform both DC and a wide range of RF testing. Having this ability gives chip manufacturers a way to provide statistically meaningful information and strong justification that their devices will do the job as promised.

Why DC Testing is Important

Characterizing a semiconductor device, even devices designed to work in an RF application, with basic DC bias and swept DC parametric is crucial for determining that the fabrication process and the resulting device structures are working as expected. DC bias tests can reveal fabrication defects and design characteristics that are out of performance tolerance in the semiconductor. Under elevated stress testing, DC parameter yield may also uncover a device's early failure mechanism. Many manufacturers rely on DC probe testing at the wafer level to identify a yield prediction of the wafer or even stop further processing of a bad, low-yield, wafer.

Performing DC tests early in the device fabrication stages allow manufacturers to adjust process steps in the production line and eliminate or at least identify low-yield wafers. Low yield wafers have many devices on the wafer that will not meet design specifications guaranteed by the manufacturer to the customer. Parts that do not meet the required performance specifications are not useable and thus cause the cost per useable device to be high in the manufacturing line. Low yields are not acceptable in semiconductor fab lines and must be investigated, understood, and alleviated as soon as possible.

Devices to be used in the implementation of 5G infrastructure equipment must be fabricated from wafer to wafer with a high yield and predictable performance in order to meet tight specifications and low-cost goals demanded by the market.

Since DC testing is a traditional metric used by semiconductor manufacturers on the production line, the tendency for the manufacturer to promote DC testing as a sufficient test for simulating RF performance is a natural aspiration. This may be very appealing to the device manufacturer since DC tests and test parameters are already instilled in their production line, however, end-users have found from field failures that this short cut is too risky.

What RF Testing Accomplishes

While DC testing demonstrates that the semiconductor process line is fabricating devices within specific performance tolerance guidelines, it does not provide information about how well a device is going to perform in a specific application, especially an RF power application. RF characterization testing on the device, at the wafer level, and at the device package level, is a superset of test data that validates the device’s adherence to specification levels expected by the end-user and most likely guaranteed by the manufacturer’s datasheet.

In addition, RF performance with age is a primary metric required by the customer in reliability verification of the technology and chip design. Therefore, manufacturers that are working to deliver high yield wafers for stringent RF applications have begun to adopt levels of RF testing on the production line and in the back-end processes to increase the probability of ending up with a “known good” device for shipment to the customer.

Ready to explore the testing parameters required by the 5G ecosystem?

In a 5G infrastructure market, performance degradation is a parameter that manufacturers cannot guess at. Knowing the rate at which a device will start to lose functionality and degrade the network is paramount in assessing the cost of scheduled maintenance and expected equipment replacement programs.

Not having precise statistical data on when a device will need replacement would lead to high risks of customer dissatisfaction as calls and information are interrupted or lost due to network re-routing to bypass unavailable RF transmitters. Constant repairs caused by faulty parts would result not only in a reduction in the user’s confidence in the 5G network as a whole but a lack of trust in the service provider’s ability to live up to its promises.

Testing RF Devices for Reliability Assurance

Heat is the primary reason for the shortening of lifetimes in semiconductor devices. High temperature can be environmentally driven, but self-heat generated by the chip is most likely to drive a short lifetime. The reasons for semiconductor performance degradation with temperature typically fall into categories known as device failure mechanisms. Each failure mechanism can be a chemical, electrical, or mechanical condition that causes a change in the device characteristics that will degrade performance and eventually drive catastrophic damage. Typically, a semiconductor will have one dominant failure mechanism with secondary failure mechanisms also occurring. The dominant failure mechanism will be the primary limiter of the reliability of the device. The rate-of-change of the dominant failure mechanism will be much greater than the combination of all secondary mechanisms. In this case, an accelerated life test can be determined to specifically drive the dominant mechanism with elevated stress levels (voltage, current, or electric-field) as a function of temperature.

The case of a dominant failure mechanism is a simple but realistic assumption most of the time, however, for high power RF devices typically used in transmitter applications, this is not a good assumption. In high power RF devices, the RF signals produce variations of voltage and current components as alternating signals, AC equivalent signals, which cause a sinusoidal or other modulational components of stress in the device. These RF signal stresses can cause DC component signals to be pulled or alternate between values as the RF signal is applied. The RF signal can drive a temperature level in the device or cause molecular changes in the semiconductor structure as the RF is applied due to quantum effects. The variety of conditions that exist with RF signal excitation cause a combination of failure mechanisms such that not one single failure mechanism is now dominant. In fact, there are at least three failure mechanisms that can combine to cause a composite lifetime determinant in the device.

As the discussion above describes, adding RF signals on a semiconductor causes a variety of equivalent DC signal levels to exist as the RF signal swing, the AC component, alternates on the transistors of the chip. Since the alternating DC levels can be modeled as the RF signal is presented to the device, some theorists have surmised that a series of DC tests can simulate an equivalent RF lifetime with some accuracy. To achieve this approximation the device would need to have several individual DC bias tests performed and then a composite lifetime calculated. This would require testing at various equivalent conditions of the RF signal, which would be at least 4 different DC test conditions. However, the cause of a device's declining RF performance is rarely a result of a single DC factor and, as stated, is a composite of several failure mechanisms. In other words, even four DC tests cannot give the precise picture of one RF test for a device used as an RF power transmitter when it comes to predicting lifetime and performance degradation.

Some manufacturers have adopted a DC only test syndrome simply because it is a familiar test in their production line and DC testing does not require purchasing additional equipment to add the RF signal. In addition, RF testing has a stigma for some of being a “magic art” and RF is difficult to perform and interpret results. This is a condition that is becoming less and less tolerable to the RF industry, however. With a history of field failures, most customers of RF device manufacturers are beginning to specify in their acceptance terms that some form of RF testing is done to qualify parts for RF power applications. As markets continue to be driven by RF performance, key metrics of acceptable testing requirements will have RF testing as a prerequisite.

In it For The Long Haul With Accel-RF And 5G

Manufacturing semiconductors is a highly competitive industry. Chipmakers must show that their devices are reliable in the application in which system integrators intend to use them. Short-term strategies of cutting corners by circumventing adequate reliability testing will almost certainly backfire.

Partnering with a leader in the industry like Accel-RF is a strategy that can help build a manufacturer's reputation as a provider of “known good” devices. Accel-RF has been a trusted name in reliability testing solutions for decades. The company's founders and principals have played a role in helping to set the standards for what constitutes adequate testing for high stakes applications like the 5G network infrastructure.

Accel-RF’s modular, adaptable systems allow their customers to scale test capabilities as needed. Customers have the option to start with a base unit that meets today’s needs and then add additional modules for higher RF power or frequency as required. The innate flexibility of the Accel-RF platform improves the return on investment of their customer’s test system by adapting to their development roadmap as it evolves over time. Users pay only for capability needed now but have the flexibility to adapt to new requirements quickly and in the same platform already purchased. This improves the schedule and cost of new product development and time to market.