Many things can go wrong in the testing process, causing unpredictable and expensive setbacks. For example, imagine being weeks, months, or even years into developing a design, only to discover that an overlooked crucial detail in the package design stage of the reliability testing process has thrown the device’s reliability into question. In the tight margins and rapid pace of electronics manufacturing, this could spell disaster.

The above scenario is not at all uncommon. The sudden influx of new materials (i.e., GaN) and the explosive growth of RF device development have worsened the problem. Additionally, companies often defer reliability testing to the end of a project, and many also underestimate its complexity.

For many, it’s worthwhile to consider some additional testing services to help eliminate risk and ensure more accurate test results.

Accel-RF: Your Advantage in the Semiconductor Arena

With decades of experience in all areas of the semiconductor reliability testing process, Accel-RF can offer expert advice for the challenges you face. The diversity of disciplines represented by the team of testing engineers at Accel-RF can help guide you in creating a wholly turn-key testing operation. We know all the potential pitfalls, and more importantly, we offer keen insight to help you proceed with confidence.

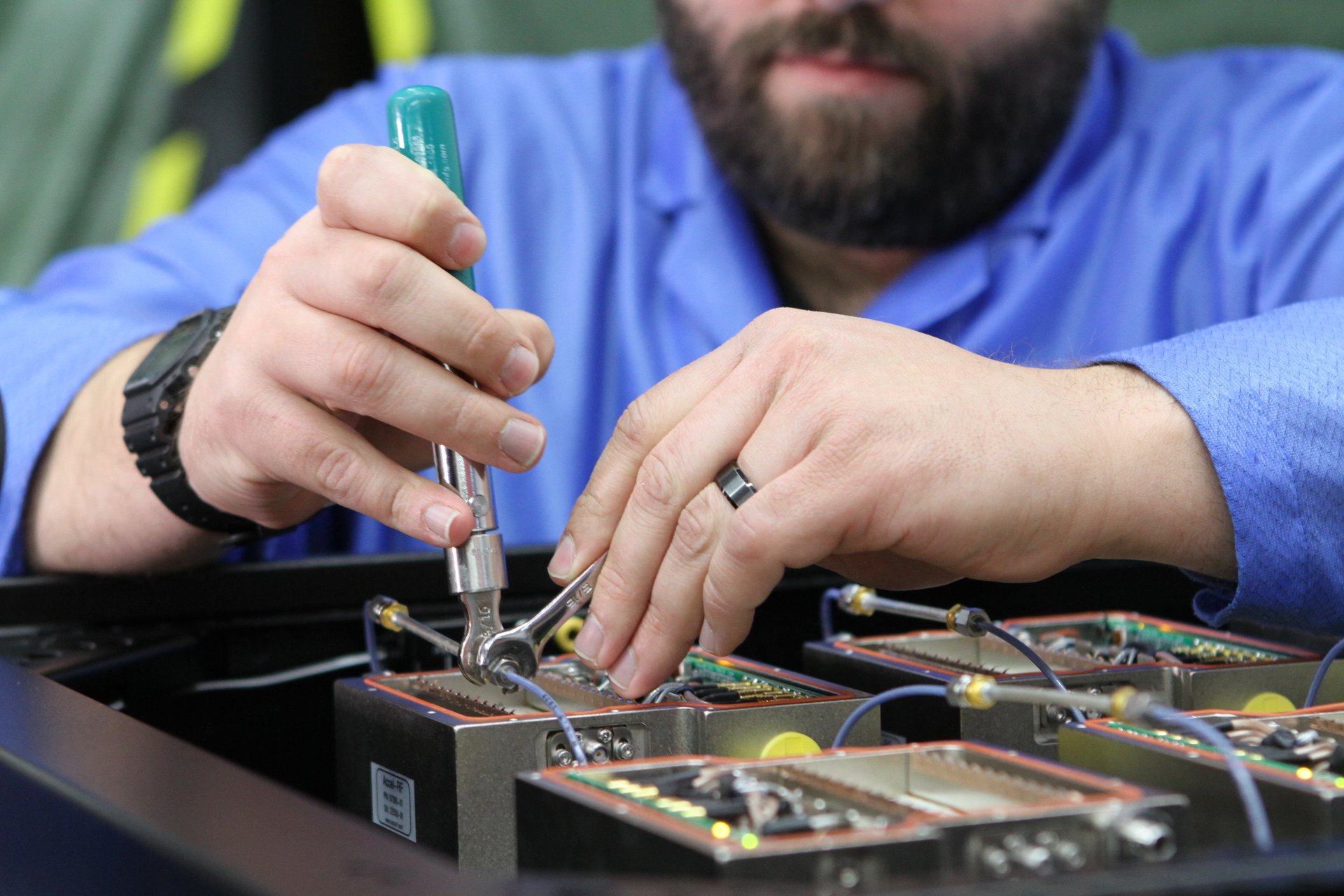

Accel-RF provides innovative modular RF testing fixtures that are unrivaled in flexibility. In addition, our LifeTest characterization software is renowned for its ability to provide the precise data manufacturers need to show their customers. Now, let’s take a look at some of the testing services device makers should seek out that can mean the difference between a successful launch or a costly failure for your next project.

1. Package Identification

One detail that can slow down a semiconductor reliability testing program, usually at the most inopportune time, is selecting the proper packaging. Often, engineers design devices with a particular commercially available IC package, adequately rated for the device’s ultimate use, in mind. The plan is commonly to use the selected package when it’s time for reliability testing.

On the surface, this idea makes perfect sense. But there is one aspect of the testing process that can make using its ultimate packaging a big no-no – extreme heat.

For example, depending on the product and its eventual use, the package may need to bear temperatures of 100°C. However, the accelerated aging process necessary to conclude how the device will perform over years, or decades, typically involves subjecting the device to temperatures up to 300-400°C. Therefore, the reliability test package design has to withstand elevated temperatures while allowing stable operation during RF testing.

Wide-ranging experience in semiconductor reliability testing has given the Accel-RF team expertise to know if a reliability test package design will meet your requirements or not. In addition, we know what is commercially available, and we understand how to determine the thresholds of temperature testing, so we can advise you on the best, most efficient package to use for your tests.

2. Custom Reliability Test Package Design

Entry into the world of compound semiconductors and RF (up to mmWave) chip design requires engineers to spend a substantial amount of time selecting the correct package for their device. Often, no standard commercial package will be available. In this case, the chipmaker must outsource the design and manufacture of a custom package.

Handing off this critical component of a product rollout can be nerve-racking. The new standards in ICs, which include much higher bandwidth and power dissipation requirements, make it hard to know which package makers are up to the job.

Whoever is selected must take particular care to minimize the effects of operating at the high end of the RF spectrum. Lead lengths suddenly become critical as parasitic traces’ excessive inductance or capacitance can destroy the device’s performance. Specialized knowledge is needed to determine how the reliability test package design will affect the operation of the device.

In some cases, they must also understand the effects of increased power dissipation requirements for newer compound semiconductors. In this expanding market, it can be difficult for designers to locate the right third party to handle this crucial part of the manufacturing process.

Again, Accel-RF’s experience and industry contacts come into play. We can help you determine what your device requires for a package, and we know where to guide you to find the right firm to make what you need.

3. First Article Testing as Proof of Concept

When a design is brand new, it is still theoretical. However, physicists and engineers can predict how the device will most likely perform with some degree of accuracy. Companies then begin making plans, allocating budgets, and working on sales and marketing campaigns based solely on this unproven but highly feasible idea.

Eventually, the day will come when it is time to make the first unit to prove the concept can become a reality. Unfortunately, things can quickly become bleak for the design team if they run into significant problems producing a working prototype that can pass first article testing and prove mass-production is possible. Trouble at this point can often torpedo the whole project.

What could go wrong? The company is only asking the engineers to operate an untried device in an unfamiliar package at extremely high temperatures on, in most cases, a test fixture that they have no experience using. In reality, plenty can go wrong and often does.

Since our customers are using our equipment and trusting our expertise, Accel-RF actively ensures that the first article testing is successful. And, we are confident that we are going to be close on the first try. After all, we bring RF testing engineers, mechanical engineers, thermal engineers, and over 25 years of experience.

We help investigate and discover any problems to make first article testing as painless as possible. Our commitment in this area saves our customers precious time.

4. Matching Circuit Design Process

As mentioned previously, operating circuits at the extreme high end of the electromagnetic spectrum can cause some seemingly unpredictable results. Consequently, designing matching circuits for these frequencies is not trivial. To get accurate results for semiconductor reliability, engineers must carefully calculate impedances for every supporting component, lead, and, just as importantly, for the test fixture itself.

Getting the matching circuit right is a delicate process, and it takes an intimate knowledge of the device, the auxiliary circuitry of the design, and the testing fixture. The process is a joint effort between Accel-RF and our customers that typically works something like this:

- Engineers working on the chip design collect load-pull (impedance matching) data from a wafer probe system.

- Accel-RF takes that data and “embeds” it into our test fixture that we have already characterized.

- Accel-RF then develops a matching circuit designed to keep the device stable at high temperatures and operating at RF frequencies.

The matching circuit design represents a close partnership between our customers and us. They supply the device, we provide the fixture, and we combine our understandings of our respective parts of the process. The result is a fully characterized circuit so the chip designers can focus on getting accurate semiconductor reliability data for their device without interference from external factors.

5. Contract Assembly Services

The assembly of the package for testing is the final element that chip manufacturers often take too lightly. Of course, the chipmaker can worry about fabrication for mass production later, but for semiconductor reliability testing purposes, the process is just as necessary. At this point in the process, the last thing the testing team needs is skewed results caused by a faulty or mischaracterized package assembly.

Extra precision is necessary for this process to allow for the extreme conditions the device will undergo during testing. For example, a void in a trace or another imperfection can cause additional heat or interfere with RF operation.

The assembly process must follow the correct fabrication hierarchy, use high heat resistant solder, and include every possible technique to remove other potential problems from the test paradigm. Companies that have mastered this level of assembly proficiency are rare and hard to find. However, that’s where our industry knowledge becomes a real benefit.

While Accel-RF doesn’t do assembly in-house, we have close relationships with companies well-versed in doing this type of work. As a result, we can guide our customers in laying out their assembly process, choosing their packaging and solders, and showing them how to implement the device into the package. In addition, we know what it takes to do high-temperature testing without having to spend valuable time tracking down problems caused by the package assembly.

The Right Choice for a Semiconductor Reliability Testing Partner

When the chips are down (so to speak), you want a semiconductor reliability testing partner, not a test fixture vendor. With our multi-disciplined, hands-on approach, Accel-RF fits that description. In addition, our decades of experience in device reliability testing give us a unique advantage over other companies.

We actively participate in our customers’ success by helping them to avoid common pitfalls. Of course, getting to the finish line with a successful product launch isn’t easy. Still, with Accel-RF on your team, you increase your odds of obtaining a favorable outcome by partnering with an unrivaled industry expert.