RELIABILITY TESTING

SETTING UP FOR SUCCESS

With reliability testing, it's important to plan your test strategy with your desired end-result in mind. In this demo, you'll get a detailed overview of the reliability testing process, as well as a glimpse into configuring your system to fit your reliability testing needs.

Other topics you'll learn more about in the demo include:

- Choosing the right package for your DUT

- Mounting a device to a fixture

- Identifying and tuning circuits

- Configuring fixtures

- Benchtop testing

- Thermal imaging characterization

- Mounting a fixture in a system

- Setting-up and running a LifeTest

Register now for immediate access to this on-demand product demo.

Access the Demo

Curious?

Here's a sneak peek at what you'll SEE.

.png?width=491&name=Screen%20Shot%202020-03-02%20at%204.10.04%20PM%20(2).png)

Selecting Your Test Device Package

There are a number of considerations that come into play, starting with picking an appropriately sized package that can fit the die and any other necessary components. The material makeup of the package is also critical, as different types of reliability testing require different materials. For example, compound semiconductor device testing require DUT packages made from a composite metal to maximize thermal transfer for high device power dissipation. Don't worry if you're unsure which package fits your needs — we often work with our customers to help identify the ideal package for your application.

Configuring Your Device

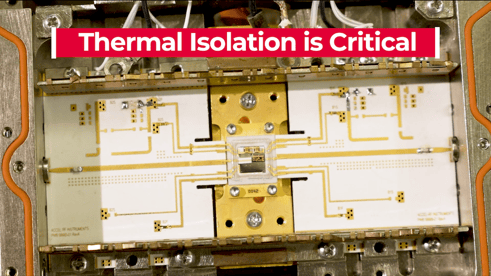

Thermal Isolation is a critical feature of the fixture for testing at elevated temperatures. Accelerated life tests can require device baseplate temperatures up to or above 250 degrees Celsius and having the entire test fixture heat up to that degree will have adverse effects. A sound mechanical design where only the device is subjected to the extreme temperatures — not the rest of the fixture — is important.

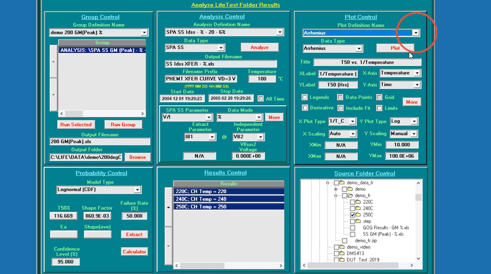

Data Analysis

When testing is complete, the collected results from each device can be reviewed using analysis- and data-extraction features built into the software. This ranges from generating plots of the measured stress data to advanced statistical analysis. Because the devices degraded gracefully to desired failure criteria, you can also remove the still-intact devices for failure analysis techniques, like FIB, SEM and TEM. You can then use these results to make changes to your fabrication process to improve the performance and reliability of future lots.